Fluid medium: Water, oil, gas and various corrosive media

Temperature Range: -10℃~120℃

Pressure Ratings: PN0.6~2.5MPa

Size Range: DN100~DN4000

Connection Type: Flanged

Connection standard: GB·ANSI·DIN·API·ISO·BS

Body Materials: Cast iron;Ductile iron;Anti-corrosion valve body components, blue epoxy resin coating

Valve seat material: 316 stainless steel

Valve plate material: Stainless steel;Ductile iron

Note: All parts can be made of different materials according to actual working conditions.

Product Features

1.Double eccentric structure design, to avoid the wear of the sealing surface, maintaining the integrity of the seal and high service life.

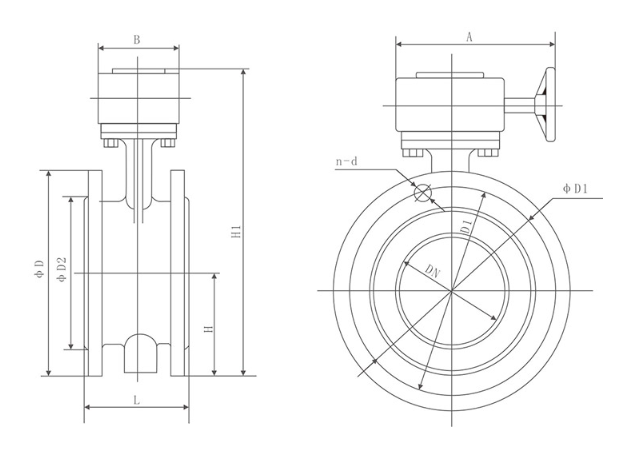

Main overall connection dimensions

|

DN |

Main overall dimensions |

Flange size and bolt hole size |

|||||||||||

|

L |

H |

H1 |

A |

B |

1.0MPa |

1.6MPa |

|||||||

|

D |

D1 |

D2 |

n-d |

D |

D1 |

D2 |

n-d |

||||||

|

50 |

108 |

82.5 |

306 |

80 |

80 |

165 |

125 |

99 |

4-18 |

165 |

125 |

99 |

4-18 |

|

65 |

112 |

92.5 |

321 |

80 |

80 |

185 |

145 |

118 |

4-18 |

185 |

145 |

118 |

4-18 |

|

80 |

114 |

100 |

346 |

80 |

80 |

200 |

160 |

132 |

8-18 |

200 |

160 |

132 |

8-18 |

|

100 |

127 |

110 |

387 |

95 |

95 |

220 |

180 |

156 |

8-18 |

220 |

180 |

156 |

8-18 |

|

125 |

140 |

125 |

411 |

95 |

95 |

250 |

210 |

184 |

8-18 |

250 |

210 |

184 |

8-18 |

|

150 |

140 |

142.5 |

447 |

95 |

95 |

285 |

240 |

211 |

8-22 |

285 |

240 |

211 |

8-22 |

|

200 |

152 |

170 |

607 |

190 |

308 |

340 |

295 |

266 |

8-22 |

340 |

295 |

266 |

12-22 |

|

250 |

165 |

192.5 |

688 |

190 |

308 |

395 |

350 |

319 |

12-22 |

405 |

355 |

319 |

12-26 |

|

300 |

178 |

222.5 |

742 |

190 |

308 |

445 |

400 |

370 |

12-22 |

460 |

410 |

370 |

12-26 |

|

350 |

190 |

252.5 |

797 |

190 |

308 |

505 |

460 |

429 |

16-22 |

520 |

470 |

429 |

16-26 |

|

400 |

216 |

282.5 |

930 |

270 |

466 |

565 |

515 |

480 |

16-26 |

580 |

525 |

480 |

16-30 |

|

450 |

222 |

307.5 |

975 |

270 |

466 |

615 |

565 |

530 |

20-26 |

640 |

585 |

548 |

20-30 |

|

500 |

229 |

335 |

1065 |

270 |

466 |

670 |

620 |

582 |

20-26 |

715 |

650 |

609 |

20-33 |

|

600 |

267 |

390 |

1225 |

457 |

625 |

780 |

725 |

682 |

20-30 |

840 |

770 |

720 |

20-36 |

|

700 |

292 |

447.5 |

1343 |

457 |

625 |

895 |

840 |

794 |

24-30 |

910 |

840 |

794 |

24-36 |

|

800 |

318 |

507.5 |

1436 |

457 |

625 |

1015 |

950 |

901 |

24-33 |

1025 |

950 |

901 |

24-39 |

|

900 |

330 |

557.5 |

1616 |

598 |

853 |

1115 |

1050 |

1001 |

28-33 |

1125 |

1050 |

1001 |

28-39 |

|

1000 |

410 |

615 |

1711 |

598 |

853 |

1230 |

1160 |

1112 |

28-36 |

1255 |

1170 |

1112 |

28-42 |

|

1200 |

470 |

727.5 |

1971 |

598 |

853 |

1455 |

1380 |

1328 |

32-39 |

1485 |

1390 |

1328 |

32-48 |

|

1400 |

530 |

837.5 |

2218 |

860 |

1345 |

1675 |

1590 |

1530 |

36-42 |

1685 |

1590 |

1530 |

36-48 |

|

1600 |

600 |

957.5 |

2578 |

860 |

1345 |

1915 |

1820 |

1750 |

40-48 |

1930 |

1820 |

1750 |

40-56 |

|

1800 |

670 |

1057.5 |

2689 |

860 |

1345 |

2115 |

2020 |

1950 |

44-48 |

2130 |

2020 |

1950 |

44-56 |

|

2000 |

760 |

1162.5 |

3022 |

952 |

1592 |

2325 |

2230 |

2150 |

48-48 |

2345 |

2230 |

2150 |

48-62 |