Fluid medium: Water, oil, gas and various corrosive media

Temperature Range: -10℃~120℃

Pressure Ratings: PN1.0~1.6MPa

Size Range: DN50~DN1200

Connection Type: Double folder

Connection standard: GB·ANSI·DIN·API·ISO·BS

Body Materials: Cast iron;Ductile iron;Carbon steel;Stainless stee;Aluminum bronze

Valve seat material: Rubber

Valve plate material: Stainless steel;Aluminum bronze;Ductile iron

Note: All parts can be made of different materials according to actual working conditions.

Product Features

1.Reduce the rotational torque, support the stem, and make it separate from the valve body effectively, reduce the wear of the valve stem.10.Apply to handle control device (DN50~300), worm gear, electric and pneumatic control device.

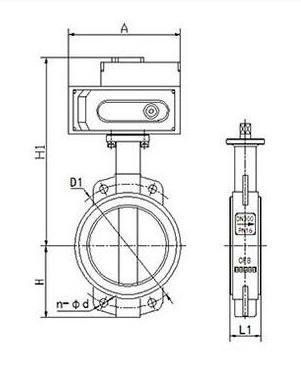

Main overall connection dimensions(PN1.0/1.6MPa)

| DN(mm) | A | B | L | D1 | n-Φ | K | E | 4-Φ1 | Φ2 | G | WT(kg) |

| 50 | 140 | 80 | 43 | 125 | 4-19 | 77 | 57.15 | 4-6.7 | 12.6 | 100 | 3.34 |

| 65 | 152 | 89 | 46 | 145 | 4-19 | 77 | 57.15 | 4-6.7 | 12.6 | 120 | 3.94 |

| 80 | 159 | 95 | 45.21 | 160 | 8-19 | 77 | 57.15 | 4-6.7 | 12.6 | 127 | 4.05 |

| 100 | 178 | 114 | 52.07 | 180 | 8-19 | 92 | 69.85 | 4-10.3 | 15.77 | 156 | 5.48 |

| 125 | 190 | 127 | 55.5 | 210 | 8-19 | 92 | 69.85 | 4-10.3 | 18.92 | 190 | 7.66 |

| 150 | 203 | 139 | 55.75 | 240 | 8-23 | 92 | 69.85 | 4-10.3 | 18.92 | 212 | 8.5 |

| 200 | 238 | 175 | 60.58 | 295 | 8-23 | 115 | 88.9 | 4-14.3 | 22.1 | 268 | 25 |

| 250 | 268 | 203 | 68 | 350 | 12-23 | 115 | 88.9 | 4-14.3 | 28.45 | 325 | 31.4 |

| 300 | 306 | 242 | 76.9 | 400 | 12-23 | 140 | 107.95 | 4-14.3 | 31.6 | 403 | 45.9 |

| 350 | 368 | 267 | 76.17 | 460 | 16-23 | 140 | 107.95 | 4-14.3 | 31.6 | 436 | 54 |